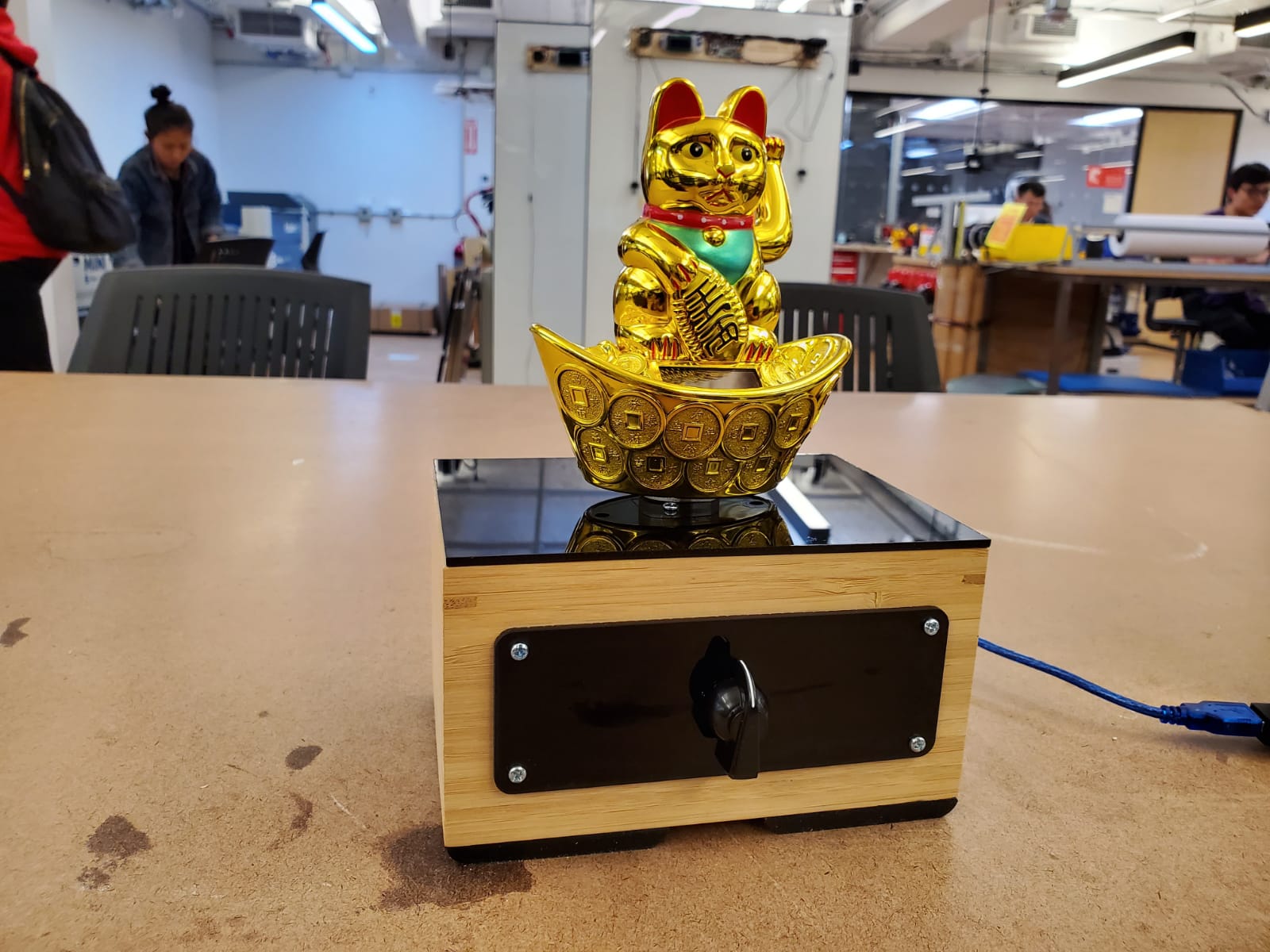

A fortune cat is a popular figurine among Asians. The eternally waving hand of the cat has magical properties that allow it to pull in good luck and prosperity into a business. With the hope of amplifying its luck-pulling abilities, I decided to start a project: a rotating fortune cat. That way the cat can pull in good luck from all directions, not just the front.

I started with the motor. I bought some panel-mounted stepper motors. They were very easy to mount but are pretty tricky to get up and running. I also added a potentiometer in there to control the speed and direction of the rotation. Here is the code I used to get the motor running.

After I got the electronics working, I dove into the assembly and fabrication process. I used a 4in by 6in bamboo box for the enclosure. The first thing I try to do was figure out the mounting for the potentiometer. At first, I wanted to use a sliding potentiometer just because it looks nice. I created a few prototypes until I landed a design that fit well.

It took some drilling and Dremel work to create the hole that will fit the potentiometer. After some time though, I was able to create the appropriately sized hole for the sliding potentiometer.

After that, I mounted the Arduino and motor driver into the box using standoffs.

However, sometimes luck is just not on your side even though you have a lucky cat with you. During the soldering process, I accidentally broke my sliding potentiometer, and I didn’t have time to buy another one. Plan B it is. I ended up having to use a rotating potentiometer instead. I had to create another mount and I had to adjust the hole to fit a taller potentiometer.

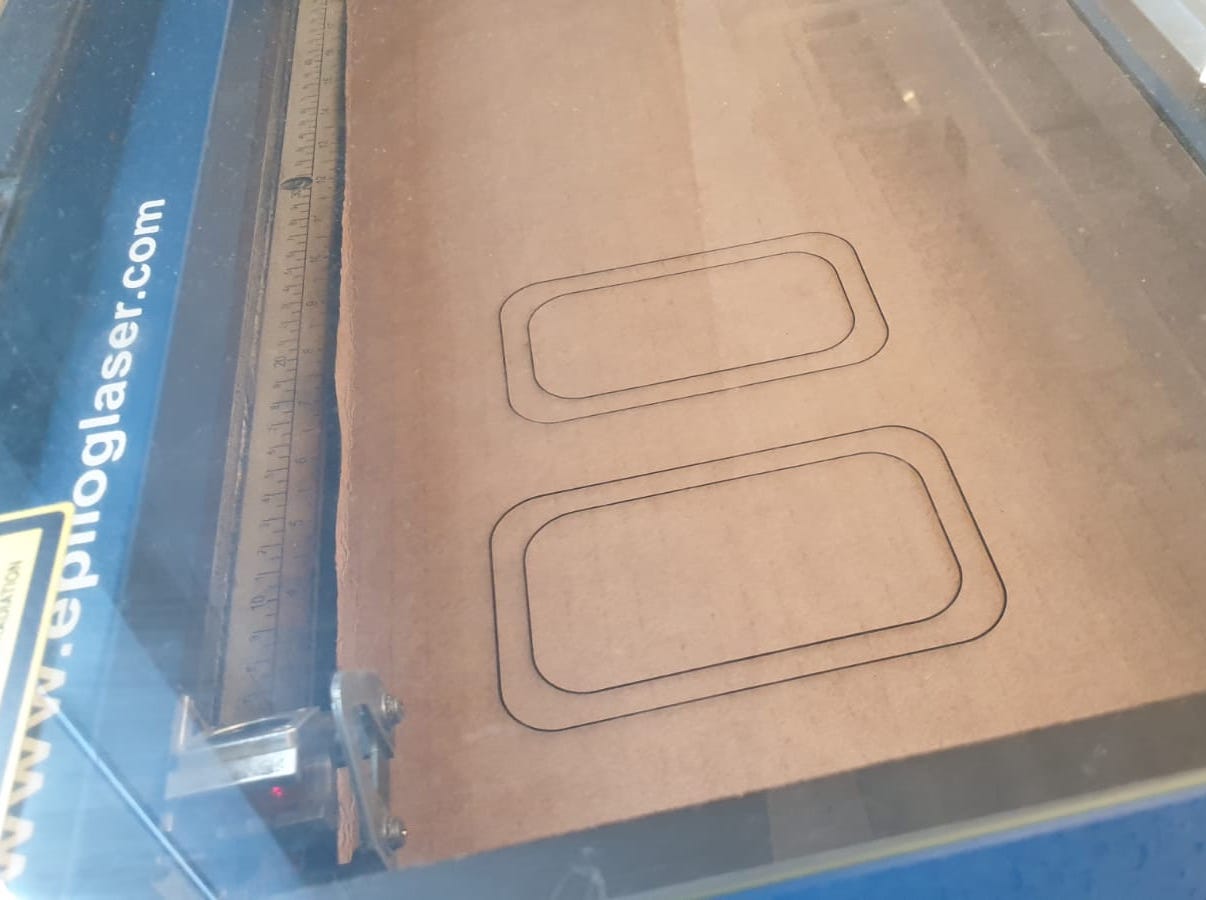

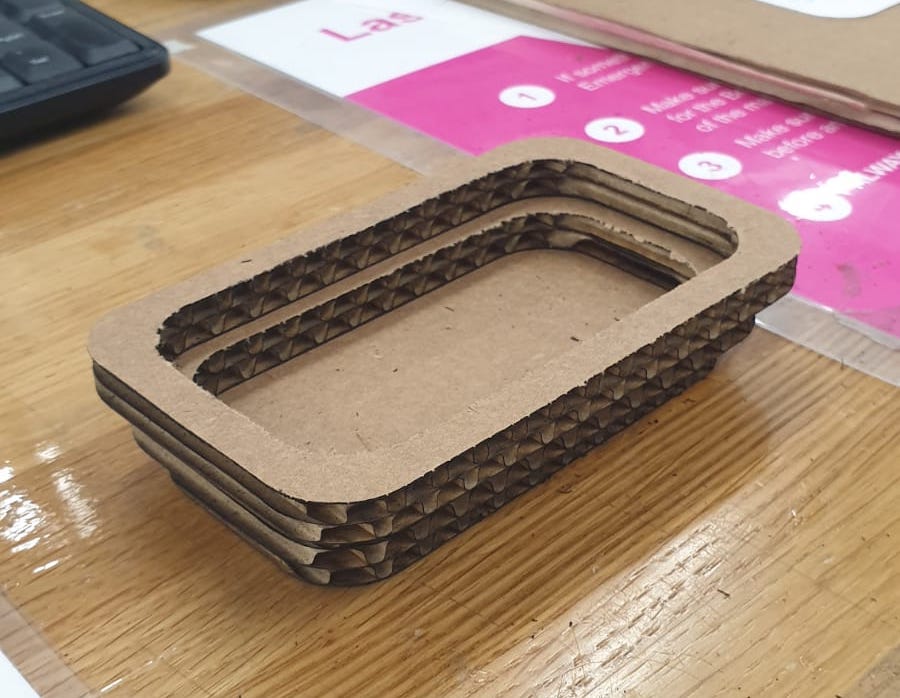

The final big thing to do is to create the lid and mounting for the cat. I made the lid out of acrylic using the laser. I did a few prototypes using cardboard first to make sure that the mounting holes are exactly right. I had also made the mounting for the cat using acrylic on the laser cutter.

Lastly, I assembled everything together and added some black rubber feet at the bottom to make it look nice, and it turned out to be amazing!